Aqua-feed Trial

Media Type

Case StudyDate posted:

19th January 2022

Share post:

A trial was conducted by a commercial fish feed producer who exports aqua-feed all over the world.

Due to transport challenges associated with shipping product to tropical regions the company reduces their feed moisture to below 6% to reduce the risk of microbial growth occurring.

Treatments

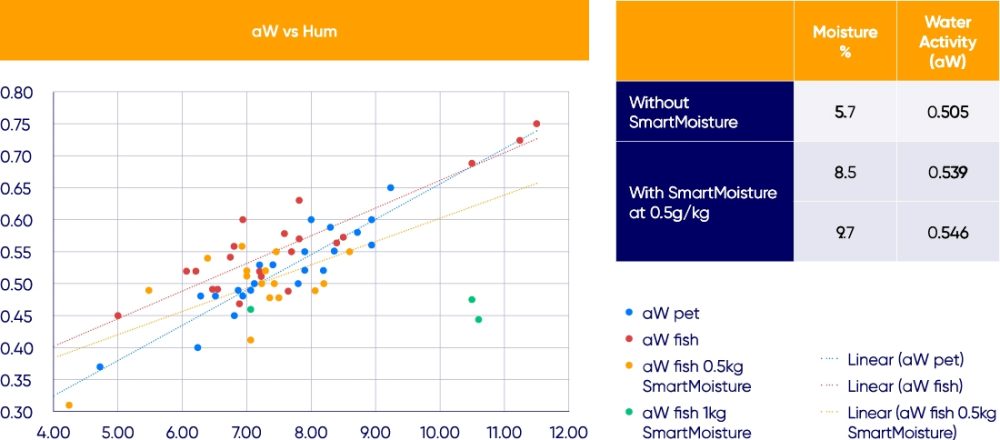

Control: No SmartMoisture with moisture level reduced to 5.7% Treatment 1: 0.5g/kg SmartMoisture with moisture level reduced to 8.5% Treatment 2: 0.5g/kg SmartMoisture with moisture level reduced to 9.7%

SmartMoisture was added in the mixer with all the usual liquid additions. Water activity was measured for all three treatments.

Results

Water activity was stabilised and even at a 4% moisture increase over the control, SmartMoisture achieved water activity below 0.55. The humectant properties of SmartMoisture stabilised the water activity when the aqua-feed was left at a higher moisture content. The propionic and formic acid, as part of the glycerol esters, were absorbed into the feed particles ensuring a stable product that is protected against microbial growth.

This gave this customer confidence to ship feed at higher moisture content, thereby increasing yield and profitability.

Advantages for the feed mill

- Yield increase

- Energy saving

- Improved steam absorption

- Save feed protected by low water activity and stable organic acids

For more information and to see how SmartMoisture works, contact us today

Enquire today