Smart Moisture - Improving cost and efficiency of aquafeed production

Media Type

News PostDate posted:

12th October 2023

Share post:

The global challenge of driving efficiencies

Feed represents over 50% of the production cost in intensive aquaculture. Soaring ingredient and energy costs have resulted in significant feed price increases in recent years, and it seems highly unlikely that these will drop significantly anytime soon.

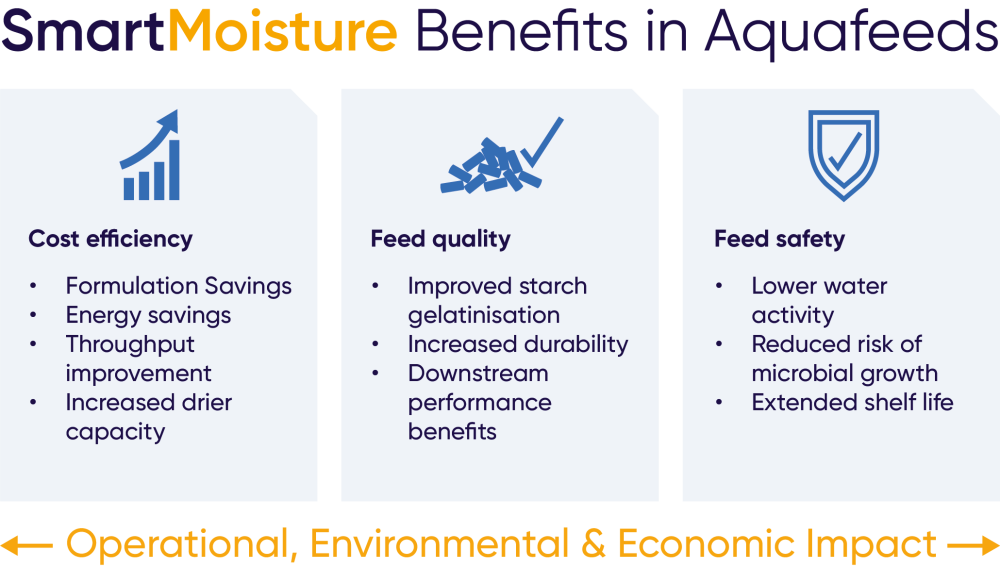

Managing cost in aquafeed production is becoming increasingly important. Any strategy to reduce cost has to find a balance between optimal formulation cost and impact on production efficiency, whilst also maintaining feed quality, and fish and shrimp performance. A common but misunderstood component and one that has a direct impact on the cost and efficiency of aquaculture production is moisture management.

The role of moisture in aquafeeds

Aquafeed requires high moisture addition during processing. Moisture is added at various stages of production to ensure optimal cooking and starch gelatinisation for pellet binding and expansion which is important for post-extrusion oil addition and consistent pellet quality.

Moisture extends its role to the safety of aquafeeds. Hot temperatures cause water to migrate during storage, while humid conditions will result in condensation, both resulting in higher activities of free water and facilitating microbial growth. By managing water activity (aW) during processing, storage, and transportation, the proliferation of microorganisms can be reduced and ensure aquafeed safety.

It is not just about optimising and safeguarding the current levels of moisture, but also increasing them. Elevated levels of moisture in aquafeeds have been well documented to result in much better absorption of nutrients by the fish and shrimp. This creates a lot of downstream performance benefits, such as improved feed quality and durability, and increased feed intake and performance.

How SmartMoisture improves cost efficiency, quality, and safety

The patented technology of SmartMoisture is based on a unique blend of glycerol esters of propionic acid, and surfactants. Glycerol acts as a humectant and emulsifier and can hold up to 1,000 times its own weight. The surfactant reduces water’s surface tension and consequently improves moisture distribution. Glycerol and the surfactant improve water absorption into the aquafeed particles, facilitating steam uptake during extrusion. Aquafeed raw materials need to absorb moisture in a very short period of time, and this is becoming more of a challenge with the increasing inclusion of vegetable raw materials. Vegetable ingredients are generally hydrophobic and do not easily absorb moisture. This results in the requirement to add additional moisture which has the effect of increasing drying times, energy consumption, and reducing production throughput.

More efficient starch gelatinisation and superior pellet quality are effects of increased steam uptake. Specifically, improvements have been recorded in feed durability and reduced levels of dust and fines. Additionally, allowing for a reduction of starch in formulations can drive down recipe cost, by creating more space in the formulation thus widening the potential raw material basket.

It has been shown that SmartMoisture improves the absorption and retention of moisture through the aquafeed production process. This efficient use of moisture allows improvements in throughput of up to 18% (figure 1), drier capacity, and energy savings of up to €11/t (figure 2).

SmartMoisture is more concentrated than any other product on the market due to the stability of glycerol esters. The propionic acid esterified to glycerol is a patented process used to buffer and stabilise propionic acid. It increases the retention time of propionic acid in feed, ensuring a longer-lasting microbial inhibition. The rate at which mould and bacteria grow after feed processing depends on factors such as pH, temperature, oxygen availability, and most importantly, water activity of the feed. The decision on what the final moisture content will be is based on risk. Lower moisture content in the final feed is targeted considering the volume of moisture used in the extrusion process and the hydrophobic nature of aquafeed raw materials to avoid free water or high water activity. SmartMoisture technology is very effective in reducing water activity in aquafeed thereby reducing risk and allowing manufacturers to produce feed with higher moisture, improving margins.

In summary, SmartMoisture provides a holistic solution to driving down costs in aquaculture production. It provides opportunities to reduce feed formulation, energy, and production costs, whilst driving improvements in feed quality. The benefits provided are not only to the feed producer but also to the farmer. Trials with customers have identified possible savings of up to €70 per tonne of feed.

Join the number of feed mills and farmers who are reaping the rewards of SmartMoisture!