SmartMoisture: Improving sustainability in pet food production

Media Type

News PostDate posted:

2nd October 2023

Share post:

The need to improve sustainability in pet food production, be that financial or environmental has never been greater. Raw material costs have skyrocketed over the past 18 months and consumer demand to create more from less continues to intensify. So how do we as pet food manufacturers improve?

SmartMoisture, a patented moisture management solution from Devenish can help on both fronts.

SmartMoisture acts to allow better penetration of water and steam during petfood production, bind said water within the petfood kibble and reduce water activity thereby preventing mould growth.

What is water activity and what impact can it have on feed?

Moisture content merely describes how much water is in the product. Water activity describes how much of that water is free and therefore available to microorganisms for growth. Hot temperatures cause water to migrate during storage, while humid conditions will result in condensation, both resulting in higher activities of free water. The growth of microorganisms will be hindered when the water activity of a pet food reaches below 0.9 for most bacterial pathogens and below 0.67 for most moulds. By managing the water activity of pet food during processing and storage, we can reduce the proliferation of microorganisms and ensure food safety.

Heat-treatment steps can kill bacterial pathogens such as Salmonella, but moulds are stable and won’t be destroyed. This has necessitated the need for alternative solutions such as SmartMoisture.

Patented solution stabilising propionic acid

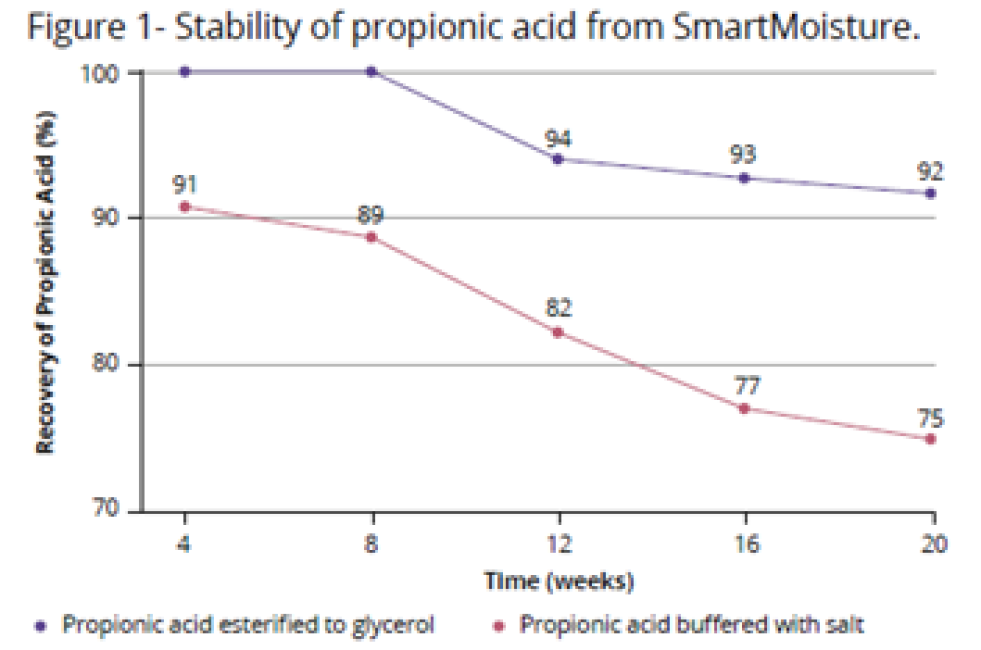

SmartMoisture consists of a combination of propionic acid esterified to glycerol, buffered formic acid, and surfactants. It is 30% more concentrated than any other product on the market due to the stability of the glycerol esters. The propionic acid esterified to glycerol is a patented process used to buffer and stabilise propionic acid (Figure 1). It increases the retention time of propionic acid in petfood, ensuring longer-lasting microbial inhibition. Glycerol acts as a humectant and emulsifier and can hold up to 1,000 times its own weight. The surfactant reduces the water’s surface tension, therefore improving moisture distribution. Glycerol and the surfactant improve water absorption into feed particles and help to stabilise water activity.

European pet food trial

In a recent trial, a European pet food producer faced transport challenges associated with shipping pet food to tropical regions. As such, the company kept pet food moisture levels below 7% to reduce the risk of microbial growth.

The trial assessed two treatments:

- Control: No SmartMoisture with moisture level reduced to 7%

- Treatment: Maximum of 750g/ton SmartMoisture inclusion with moisture level ‘increased’, or ‘dried to’ to 9%

SmartMoisture was added in the mixer with all the usual liquid additions. Samples were taken after production and at bagging. Moisture percentage and water activity were measured.

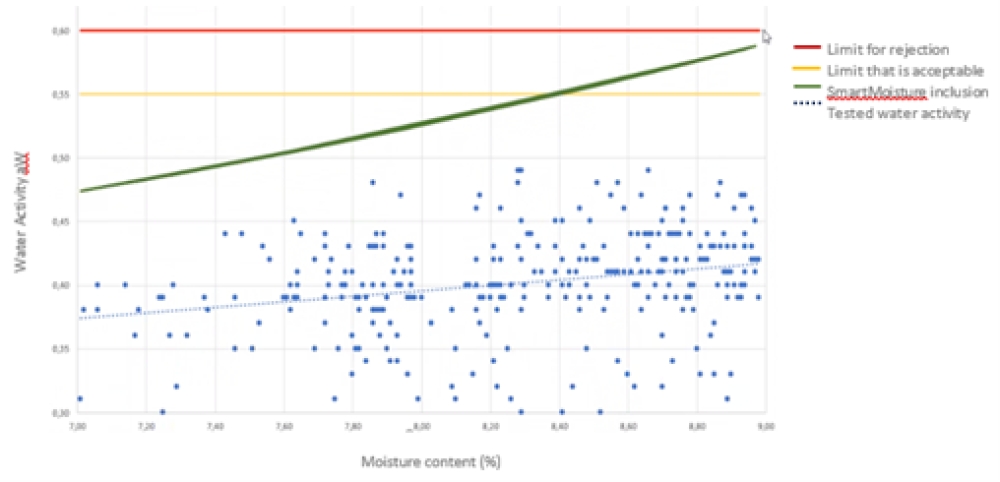

Results: Reducing water activity with a higher moisture content

SmartMoisture consistently kept aW below 0.5 even at higher moisture levels, thus allowing the dog food to be dried off to a higher moisture content. Bulk production increased without compromising quality. Throughput was also improved with kibble spending less time in the dryer and cooler.

The humectant properties of SmartMoisture stabilised the water activity when the dog food was dried to a higher moisture content. The propionic and formic acid, as part of the glycerol esters, were absorbed into the feed particles ensuring a stable product that is protected against microbial growth.

This gave this customer confidence to ship food at a higher moisture content, thereby increasing yield and profitability.

A second trial, carried out by another dog food manufacturer delivered similar results. Additional moisture was included at 2% with a water/SmartMoisture solution. Final moisture saw an increase of up to 3% in the final dog food with water activity remaining within the targeted KPI levels. SmartMoisture gave improvements in production efficiency with extruder throughput improving up to 18.0%.

Improving product form in semi-moist production

The ability to reduce drying time, maintain higher moisture levels and keep water activity low can also have an additional benefit in semi-moist food production in improving product form.

A recent trial with a European producer of semi-moist products showed how reducing drying time not only saved energy but also improved the visual appearance of the finished product. By incorporating 0.2% SmartMoisture in the production of sausage treats, drying time was reduced by approximately 20%, resulting in a more plump, fuller-looking product and reduced production costs.

Multiple benefits for pet food producers

In summary, benefits seen from the inclusion of SmartMoisture in pet food production include:-

- Petfood moisture content can be safely increased whilst reducing the risk of mould growth and moisture migration

- Improved shelf life

- Financial and environmental sustainability benefits by reducing manufacturing costs via:

- Energy savings (kwh needed per ton of food produce

- Throughput improvements in production

- Improved product form

For more information contact your local Devenish representative.